This story first appeared in the April 2019 magazine edition of Australian Aviation.

Would you abandon a fully functioning Rolls Royce or Ferrari on the roadside after it ran out of fuel? No? Well that’s pretty much what happens when a satellite costing several hundred million dollars exhausts its onboard fuel.

Even though systems may still be fully functional, operators have no choice but to decommission the satellite, using the last of the fuel to shove it several hundred kilometres out into the so-called graveyard orbit.

And there it will remain, maybe to the end of time.

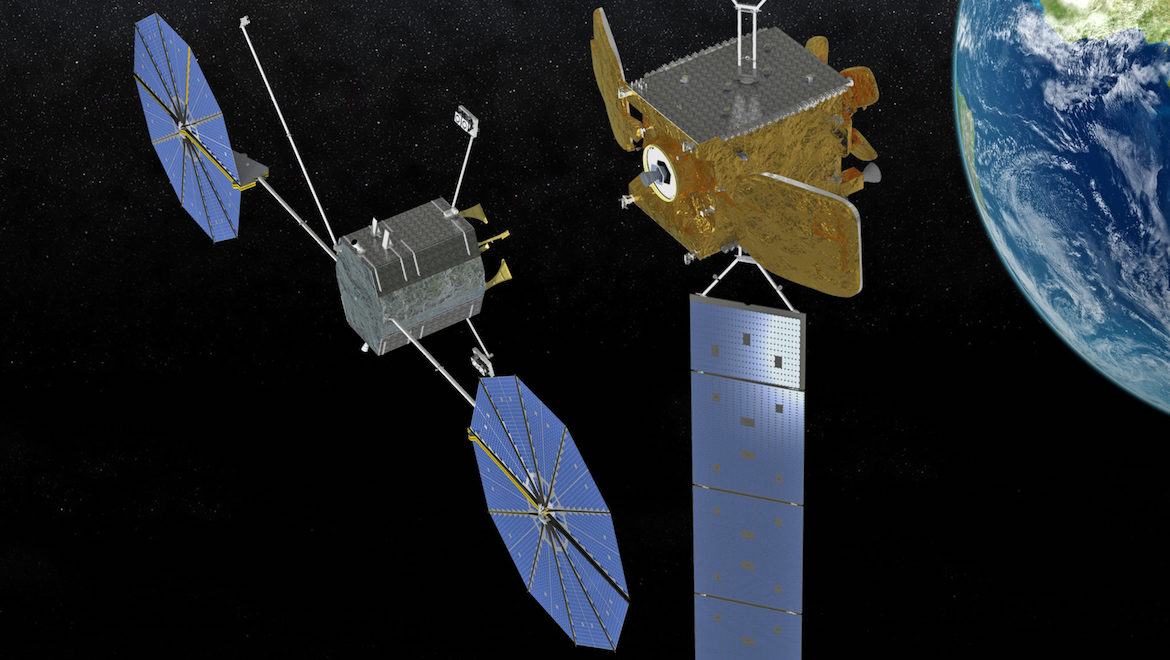

That’s set to change this year, with the launch of the world’s first space vehicle designed to link up with another satellite in orbit and extend its operational life.

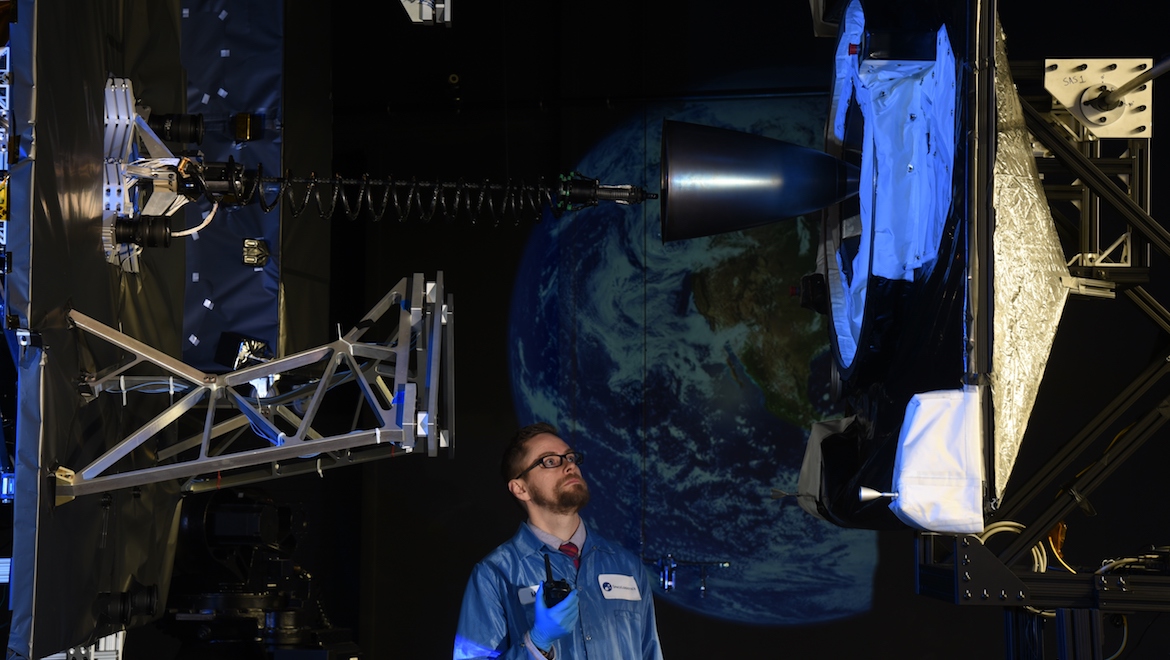

“This is really a milestone year in satellite operations, the first time a commercial company is going to rendezvous and dock with another satellite out at geo and provide a commercial service. It is going to be a big year for us,” said Joe Anderson, director of Mission Extension Vehicle (MEV) services with US defence giant Northrop Grumman.

Anderson said fuel exhaustion was the number one reason that satellites were decommissioned.

“Most of the time the components are still functioning. They simply run out of fuel,” he said.

Some satellite 101

Earth orbits are divided into three zones. Most earth observation satellites plus the space station are in low earth orbit about 320-400 kilometres up.

Other than GPS satellites, there’s not that much in medium earth orbit.

Geostationary or geosynchronous orbit – often referred to simply as geo – around 35,000 kilometres out, is where the action is. There, a satellite will remain above the one location on earth.

“In that orbit is where most of the values of satellites resides. Most all of the commercial satellites are in that orbit. There are some weather satellites, some observation imaging satellites but mostly communications satellites,” Anderson said.

Even in this high stable orbit, satellites need to maintain station and inclination and to occasionally relocate and for that they need fuel to power their thrusters.

Consequently satellite life depends on onboard fuel reserves and that has steadily improved. In the 1980s it was around nine years but it’s now around 15 years.

Anderson said 15 years was regarded as a sweet spot, balancing the technological life of satellite hardware, launch costs and the commercial horizon of satellite operators.

So why not just dock with the low fuel satellite and top up its tanks from an orbiting refueller?

The first problem is that satellites were never designed to be refuelled and to do so involves major surgery — peeling back thermal insulation, disconnecting the satellite’s original fuel plumbing, connecting to it, transferring fuel then sealing it all up again.

Doing this robotically on earth would be challenging, let alone in orbit. And you are dealing with rocket fuel here – what could possibly go wrong?

The Northrop Grumman approach is to dock its Mission Extension Vehicle with the satellite and provide all station keeping functions with its own thrusters from its own onboard fuel supply. There is no transfer of fuel and no connection, other than the physical docking.

Plenty of people have thought long and hard about how to extend satellite life and there are a number of proposals approaching reality.

UK firm Effective Space Solutions Ltd plans to launch its Space Drone in 2020. NASA plans to plans to launch its Restore-L mission in 2020 to refuel the Landsat-7 satellite in low earth orbit.

In 2021, the US Defense Advanced Research Projects Agency (DARPA) and Space Systems Loral plan to launch its Robotic Servicing of Geosynchronous Satellites (RSGS) spacecraft to perform servicing of military and commercial satellites on a fee for service basis. That could include repairs to improperly deployed antennae and solar arrays and installation of new payloads.

Northrop Grumman will be the first, launching MEV-1 this northern spring aboard a Proton rocket from Kazakhstan.

It already has a client, Intelsat, for this first mission and its second, scheduled for 2020 launch aboard an Ariane rocket.

Northrop Grumman came to this pioneering technology through its acquisition of Orbital ATK in mid-2018.

Anderson said the program formally started in 2016 when Orbital ATK decided to internally fully fund development and launch of this first vehicle.

That was preceded by extensive R and D. Anderson said he started on this project with ATK in 2012.

“We had this great concept. ATK built a lot of spacecraft components but we didn’t build spacecraft themselves,” he said.

“When we merged with Orbital Sciences and created Orbital ATK we had this great synergy. Orbital Science brought satellite manufacturing. They had the GEOStar platform.”

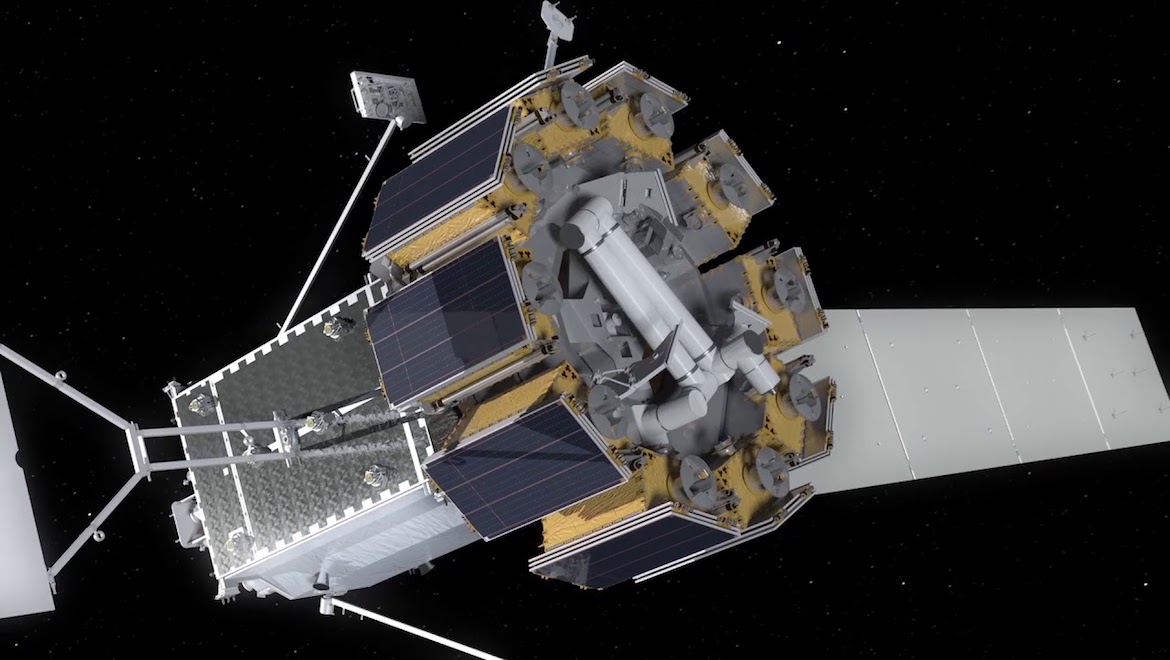

GEOStar is a family of satellite buses. The bus is that component of a satellite which provides propulsion and station keeping for the actual payload. This is mature and proven technology. The MEV will use the Gemini variant.

Orbital also had its Cygnus robotic spacecraft, used to deliver cargo to the International Space Station. It has done that successfully 10 times.

Anderson said that brought substantial experience, knowledge and capability in rendezvous and docking.

“Their docking is different to what I am doing but a lot of software and heritage and how you do those types of missions are incorporated into our MEV,” he said.

Even so, the plan was to do what no-one had done before.

“It’s been a unique process for us. This is like doing a business start-up,” he said.

“There is no established marketplace for this. The technology is kind of new. There is no regulatory environment established for doing this kind of operation.

“There are really no precedents for insurance. We are not doing a service for the government where I don’t need to insure. This is a commercial project. It needs to be insured. There are a lot of new things we had to break through to make this come to reality.”

After launch MEV-1 will steadily lift its orbit out to rendezvous with Intelsat 901 out in the graveyard orbit. That will occur around the fourth quarter of this year.

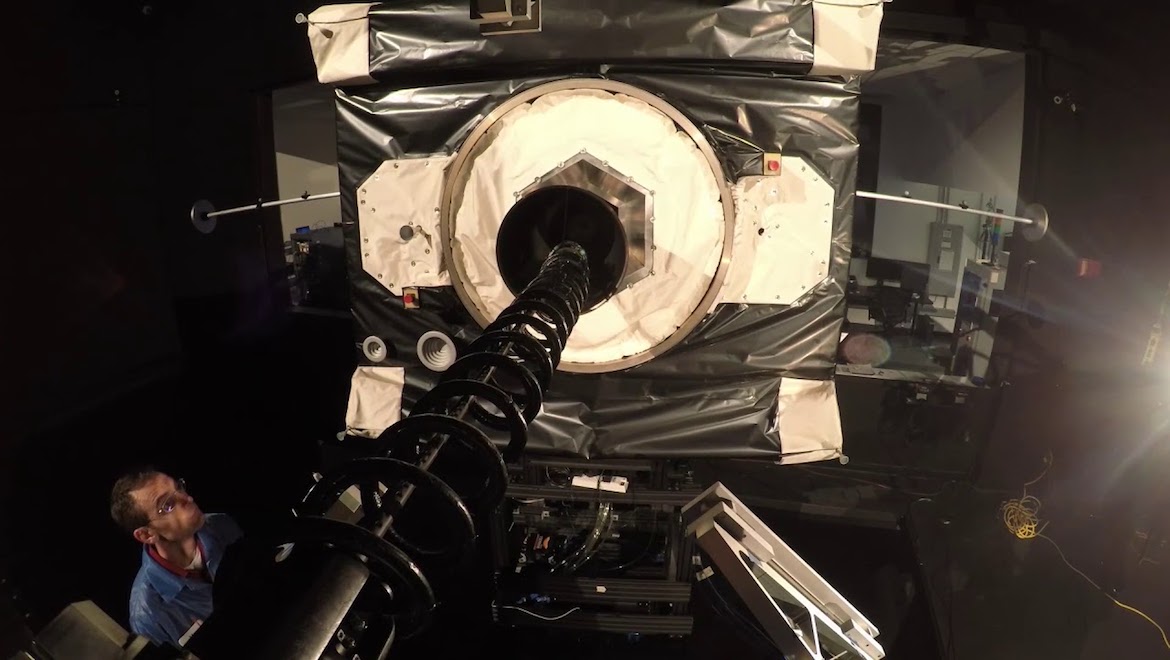

Anderson said they were performing their first rendezvous out in the graveyard orbit through abundance of caution. The MEV features onboard visual and infrared cameras and a scanning lidar for the close docking approach.

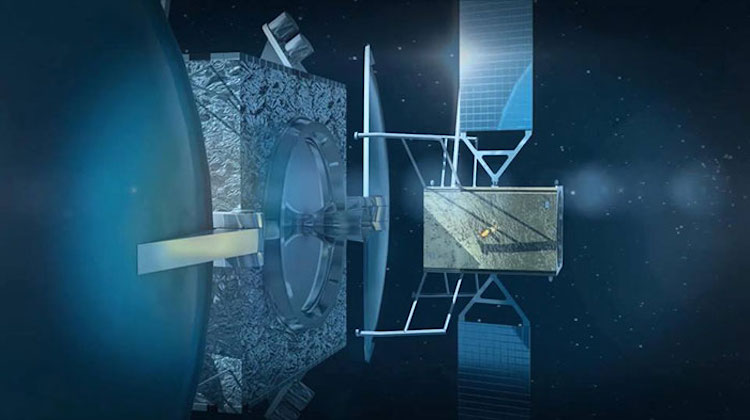

No satellite has yet been designed for docking in orbit.

But that’s possible because around 80 per cent of satellites feature a couple of common features, a standard launch adaptor ring by which it was originally attached to the top of the launch rocket and a liquid apogee engine, used to lift the satellite to geo orbit and then not used again.

The cone shaped nozzle of this engine is a perfect target for the MEV’s probe, which about a metre out, enters the nozzle throat, extends its fingers to hold on, then retracts to draw the two together.

From there, Intelsat 901, launched in June 2001, will be returned to geo orbit for a contracted five years of additional service.

Should Intelsat decide to extend the service contract, MEV-1 will stay attached. If not MEV-1 will return the satellite to the graveyard then head on to its next customer.

MEV-1 carries fuel for at least 15 years of operations.

Anderson said with a commercial satellite costing $200-300 million and a military satellite in excess of $1 billion, the value for customers was that this allowed them to defer capital expenditure. A space newcomer could even buy an older satellite already in orbit and extend its life.

“It breaks down barriers to entry for new satellite operators who want to break into this marketplace and it breaks down barriers to entry for existing operators,” he said.

He won’t discuss costs.

“Needless to say it is a really good deal for these operators. We talk about that capex deferral and this will give them very high returns,” he said.

There’s potentially much more. Northrop Grumman, though its new company Space Logistics LLC, has a grand vision, which ties in nicely with the global space renaissance.

“We have a vision that goes well beyond satellite life extension. We have a vision that takes us into in-orbit assembly, into all things space logistics,” he said.

Role for Australia?

Australia could play its part through the new Australian Space Agency and through emerging firms keen to enter the space business.

“I am looking for ways we can incorporate content in what we are doing here. I don’t have anything in mind in particular,” he said.

“I am learning about it now. We have our Australian group located there and so I will be meeting and talking to them and we will be looking for what we can do.”

So what are the possibilities for this emerging technology?

“We are also looking at in-orbit assembly and repair. We have had a contract with NASA where we are doing ground demonstrations for technologies that are needed to do assembly of very large structure in space,” he said.

“That could be very useful for things such as next generation space telescopes, for deep space transport for mission vehicles going to Mars.”

Another possibility is what’s termed a geo-tower, a structure in geo-stationary orbit which provides power and station keeping and to which satellite providers attach their own payload. That’s not too different to a common mobile phone tower.

“Operators, instead of having to launch an entire satellite each time, all they have to do is launch a payload. It’s much smaller and much simpler. They can match their payload to their customer needs,” Anderson said.

With evolving technology and emerging markets, long satellite life doesn’t seem all that necessary.

“These guys don’t know what their market is going to be 15 years from now. They don’t even know what it is going to be five years from now when the next generation satellite gets up,” he said.

“What they would really like to be able to do is start with something that just matches what they need today and then incrementally add to that over time.”

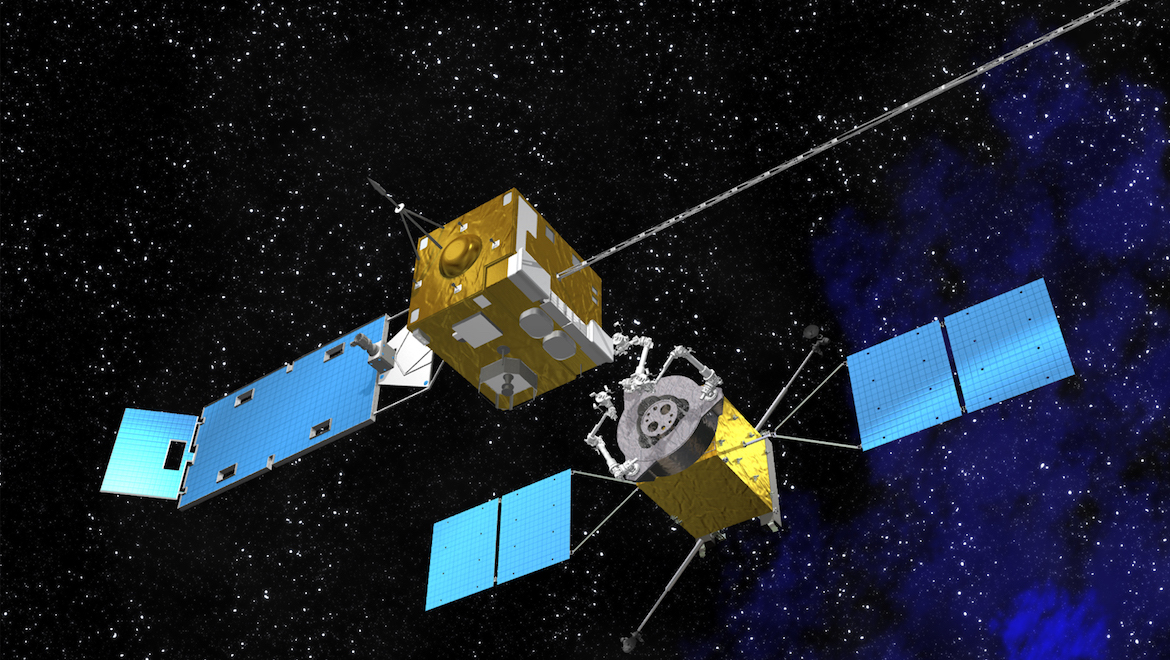

Even though the first MEV has yet to launch, Northrop Grumman is now planning a successor, last year announcing a next generation life extension process.

That’s called a mission extension pod, a vehicle about the size of a bar fridge, installed on the back of the client satellite and only performing station keeping and not attitude control and only for five years.

These would be delivered to the client aboard a mission robotic vehicle, each carrying 10 mission extension pods which are installed with a robotic arm.

Satellites aren’t designed now with any capability for refuelling or for in-orbit upgrading though installation of new modules. But it’s very likely future generations will possess this capability.

Anderson said discussions were now underway across the space industry for a standard design for the orbital equivalent of a USB port.

“If I have had a battery failure, I can come up and install a new battery – just plug into this USB port,” he said.

“I don’t have to go and do surgery on that spacecraft. I can just go and plug it into this USB port. If a sensor fails, just plug it into this USB port. I can replace failed components or I can add new capability.

“It is really enabling a revolution in the way we are doing things in space – pioneering the future of space.”

How about refuelling? Anderson said that would be possible but in line with the approach of keeping it all as simple as possible, the best means would be to attach a fresh full tank, akin to replacing a barbecue gas cylinder.

“That way you don’t have to have complicated pumping mechanisms on your refuelling space craft,” he said.

Anderson said much of this new capability could be applied to cleaning up orbiting space debris, of which vast quantities exist, with the potential to damage or destroy expensive spacecraft.

“We are not targeting that market today because there is no-one willing to pay. I can foresee the time when someone will be willing to pay for that and we will have those technologies that can support it,” he said.

VIDEO: A look at Northrop Grumman’s mission extension vehicle from the company’s YouTube channel.

This story first appeared in the April 2019 magazine edition of Australian Aviation. To read more stories like this, become a member here.