This story from the July 2019 edition of Australian Aviation look at the development of the Airbus A300 more than half a century ago.

Airbus’s A300 may not look like anything out of the ordinary today, after 50 years during which some 7,000 widebody twin-jets have been produced by Boeing and Airbus, but in 1969 it started a quiet revolution that would drive the creation of a company that would change aviation forever.

“The A300, the world’s first twin-engine widebody, is the embodiment of disruptive innovation that put Airbus firmly on the aviation map. This challenging, pioneering spirit lives on today with innovation at the heart everything we do — our aircraft, the way they are operated and the services we offer. It’s the bedrock of our success,” Christian Scherer, Airbus’s chief commercial officer and the son of A300 test pilot Günter Scherer, tells Australian Aviation.

But the A300 wasn’t always seen as a disruptive innovation, and it is more similar to its contemporary 747 than one might initially imagine, at least from an aviation industrialisation point of view. Neither aircraft was the darling of their aviation-industrial complex: supersonic transport was the future of late 1960s Kubrickian fantasy, with the 747 a stopgap that would end up as a freighter while passengers zipped around the world faster than the speed of sound, and the “air bus” as was seen as playing very much second fiddle to more exciting aviation developments.

Indeed, the Airbus project was almost scuppered by Concorde’s ballooning budget, among other hurdles that the initially Franco-German project had to clear.

Moving towards an “air bus”

Before the 747 and the A300, commercial aviation was a narrowbody affair: Boeing’s longer-range 707 and shorter-range 727, plus Douglas’s DC-8 and DC-9, dominated the market four to one, with European aircraft such as the British Aircraft Corporation One-Eleven, Sud Aviation SE 210 Caravelle and Hawker Siddeley HS 121 Trident too small for skyrocketing travel demand.

Airlines both in Europe and the United States wanted a larger and more efficient aircraft to carry some 300 people, double the capacity of the larger narrowbodies it would replace, and, ideally, using only two engines.

The rapidly consolidating aircraft manufacturers from Britain, France and a resurgent post-war Germany put in their bids, which included the BAC Two-Eleven, the Hawker-Breguet-Nord HBN 100, the Sud-Dassault Galion, and others. Some of these resembled what would become the A300, while some did not.

Proposals were drawn up by the British Aircraft Corporation, Bölkow, Breguet, Dornier, Hamburger Flugzeugbau, Hawker Siddeley, Messerschmitt, Sud Aviation and Vereinigte Flugtechnische Werke — many of which would merge, and most of which, with the exclusion of Breguet and Dornier, would end up creating the Airbus Industrie Groupement d’intérêt économique (Economic Interest Group) in 1970 that would evolve into the Airbus Group we know today.

France, Germany and Britain had agreed in 1967, “for the purpose of strengthening European co-operation in the field of aviation technology and thereby promoting economic and technological progress in Europe, to take appropriate measures for the joint development and production of an air bus.”

Europe’s governments at the time were hardly laissez-faire with their aviation markets, perhaps unsurprisingly so given World War II with all its air power dominance, and the space race in full swing between the United States and the Soviet Union.

But the politics of the time was filled with informal yet binding agreements, and so three mini-consortia were selected, each with a national company leader: Britain’s Hawker Siddeley, working with Breguet; France’s Sud Aviation, working with BAC; and a cross-German consortium called Studiengruppe Airbus, or the Airbus Study Group, which would become Deutsche Airbus.

The “Airbus” name was not universally popular in the Mad Men, Pan Am era of glamourous, caviar-and-chateaubriand flying. Air travel, still largely a luxury, was only starting to open to a larger market as early narrowbody jet aircraft trickled down to the fleets of European package holiday tour operators, shuttling sunseekers from the north to largely Spanish beach resorts.

There was certainly opposition in some corners to going from the flying equivalent of the QE2 to the Number 300 bus.

Yet the name stuck: bus means bus in Britain, France, Germany and indeed the Netherlands, which was helpful since those nations would shoulder 36.5 per cent, 36.5 per cent, 20 per cent and seven per cent (the latter since Fokker entered into cooperation with Germany’s VFW, taking its seven per cent from work previously assigned to the three major partners) of a technical investment into what would become Airbus, split according to the production percentage each nation would receive.

This kind of state seed funding – or state aid, when viewed from a different perspective – continues to raise ire today, with ongoing litigation at the World Trade Organization for a decade and a half from Boeing and the United States, and from Airbus and the European Union, about the nature and extent of governmental support for commercial aviation at national, state and local levels. Plus ça change.

Moving towards “Airbus”

Cooperation between European aviation companies did not by any means start with Airbus. High-profile partnerships like Concorde aside, structures and technologies were shared via commercial agreements across borders of an as-yet-ununified Europe.

As just one example, the Caravelle, developed by Sud Aviation predecessor SNCASE (Société nationale des constructions aéronautiques du Sud-Est, one of the pre-war nationalised consortia within French aviation), took its entire cockpit and front fuselage from the de Havilland Comet, in a transnational deal not unlike Boeing’s 707 gave its pointy end to the 727 and later 737.

But the evolution of this transnational partnership was unlike anything ever seen — and its geographical distribution of the way that aircraft are built changed the industry forever.

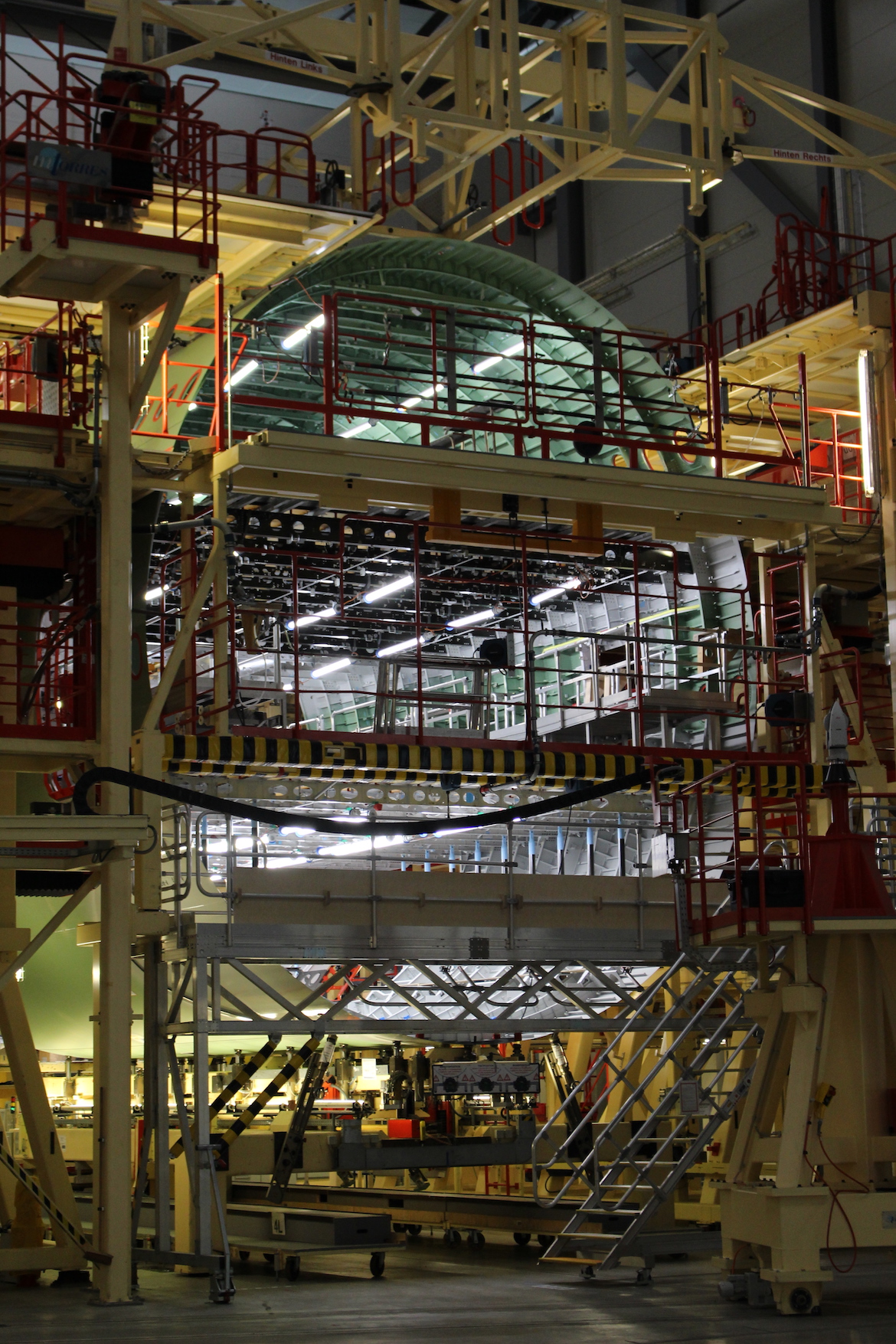

Even today, Airbus actually manufactures only one airliner part in Toulouse: engine pylons. Everything else from nose to tail is brought in substantially assembled parts to final assembly lines in Toulouse-Blagnac (the old home of Sud Aviation), Hamburg-Finkenwerder (the home of Hamburger Flugzeugbau), as well as Tianjin in China and Mobile in the US state of Alabama, key beneficiaries of Airbus’s distributed production model. Toulouse manufactures every aircraft type apart from the A220, né Bombardier C Series, while the other Airbus final assembly lines manufacture only Airbus A320 narrowbody family aircraft.

The metaphor Airbus has always used for how it produces aircraft is the Meccano set, but this undersells the crucial element that the sub-assemblies are transported around Europe (and to a lesser extent the world) mostly assembled: wings, flight controls, fuselage, empennage, flightdeck, landing gear, avionics, and more. In a modern equivalent, Airbus production is more IKEA than Meccano: some specialised tools and a bit of knowhow are needed to put specially manufactured pieces together.

To perhaps oversimplify, the pointy end and front of most Airbus aircraft are produced in France. Germany does a lot of the high-tech component work and makes the middle bits. The UK does research and makes the wings, and the back end comes from Spain. Sub-sub-assemblies and components are, of course, sourced from across Europe and indeed the world.

This split is, for the most part, how the A300 work was also divided in the late 1960s, when the three national partners — Hawker Siddeley, Deutsche Airbus and Sud Aviation — created this revolutionary way of building aircraft.

Airbus’s distributed manufacturing model seemed mad when it started: transporting pre-assembled components by boat, lorry and train across Europe, let alone in a hugely inelegant specially built cargo aircraft. But the evolution of the global aviation industry, and in particular its decentralisation, have meant that Boeing and other airframers also source pre-assembled components from internal and external suppliers worldwide.

This distributed manufacturing model also allowed Airbus to break into China while minimising the risk of unauthorised or unintended technology transfer: too much of the industrialisation and intellectual property contained in the subassemblies is retained in Airbus’s own and key suppliers’ centres to be replicable.

It is certainly no McDonnell Douglas model, where initially sub-assemblies but crucially key component production work for Chinese market MD-80 and MD-90 family twinjets were sent to a predecessor of Comac in the late 1980s. Comac’s ARJ21 regional jet bears no small resemblance to the McDonnell Douglas aircraft.

Designing the A300 . . . and the A300B, and the A300B1, and . . .

The “A-300 Airbus”, as it was originally known, was intended to be about a fifth larger than the first A300 we think of today — eventually called the A300B — ended up being. Named for the number of passengers it was intended to transport, the initial design was to be more akin to the size of the Lockheed L-1011 and Douglas DC-10 trijets being created on the other side of the Atlantic.

The original A300 (let’s call it the A300A) relied on the development of the Rolls-Royce RB207, a high bypass turbofan substantially larger than either its predecessor engines or, indeed, the RB211 that the project eventually became.

Industrial and political manoeuvring within Rolls-Royce and the UK led to a surprise announcement that Lockheed had awarded Rolls-Royce an exclusive contract to supply the L-1011 TriStar with the RB211. As it turned out, Rolls-Royce didn’t even have the capacity to produce that, leading the company into insolvency and nationalisation by the UK, dooming the TriStar’s success and spelling the end of Lockheed’s commercial aircraft ambitions.

The fledgling Airbus, having seen some of this writing on the wall, noting the expense of creating an all new engine for the project, and also rethinking the need for quite so huge a capacity jump from the 100-150-seater narrowbodies already on the market, had already started work in secret on the design for an A300B, a shorter 250-seater concept with a narrower fuselage.

Originally, the A300A’s fuselage diameter was intended to be 6.4m, fitting it somewhere between the 6.5m diameter of the Boeing 747 and the 6.2m of the 777. (Does an A300 with a wider and longer fuselage and more powerful engines sounds like a 50-year-old version of the Airbus A350?)

The A300B work was prescient not just for the 1960s and 70s but into the 1990s and 2000s: only the advent of engines the size of the General Electric GE90, Pratt & Whitney PW4000 and Rolls-Royce Trent 800 would enable twinjets to break the 6m fuselage barrier.

Length from the A to the B was also reduced, from 54m to 48m, meaning that the A300B was a full 25 tonnes lighter than the A300A.

Crucially, the smaller A300B could use engines already on the market in the 1960s: the Pratt & Whitney JT9 or the General Electric CF6. Rolls’ RB211, however, was exclusive to Lockheed and the L-1011.

Given that Rolls-Royce made up a large part of the then-UK government’s interest in the Airbus project, and despite the exposure of Hawker Siddeley to the wings, the British pulled the plug on its political and financial contribution to the Airbus programme, to be replaced by the then-West Germany, which agreed to split Airbus 50:50 with France.

German interests lay in rebuilding its post-war aviation industry, and West German finance minister Franz Josef Strauss — himself an aviator, and for whom Munich Airport is named — was key to this renaissance and integration with the rest of European aviation, not least with a loan to Hawker Siddeley to fund its A300 activities.

The teutonically bolstered Hawker Siddeley, for its part, agreed in 1969 to continue its wing work as a private company unsupported by the UK government, with the Dutch company Fokker joining later that year as part of its partnership with

the German VFW.

CASA, the Spanish Construcciones Aeronáuticas Sociedad Anónima, joined in 1971, while Hawker Siddeley merged with BAC in 1977 to form British Aerospace, which rejoined Airbus in 1979.

In France, original partner Sud Aviation itself had merged with Nord Aviation and SEREB, the Société d’études et de réalisation d’engins balistiques to form SNIAS, the Société nationale industrielle aérospatiale, later de-acronymed to become Aérospatiale, which took 59 per cent of Airbus Industrie, with the other 50 per cent taken by the Deutsche Airbus consortium. Aérospatiale would later merge with missileer and technology company Matra.

A decade and a half later, Deutsche Airbus had evolved via mergers into DASA, the Deutsche Aerospace Aktiengesellschaft, later DaimlerChrysler Aerospace. DASA, Spain’s CASA, and the combined Aérospatiale-Matra merged over a period of months in 1999-2000 to create EADS, the European Aeronautic Defence and Space Company, reorganised and renamed in 2014 to Airbus.

Continuing the evolution of the A300 — and Airbus

But back to 1969. With the removal of Rolls-Royce as a partner, the nascent Airbus programme selected General Electric’s CF6-50A as the A300B’s lead engine. Part of the deal, however, was involvement of the French engine-maker SNECMA, now part of super-supplier Safran, in the engine production.

This involvement led to a deepening partnership between GE’s aviation propulsion business and SNECMA’s, which resulted in the hugely successful CFM International joint venture between the two companies, best known for its CFM56 engine powering generations of aircraft, as well as the next-generation LEAP engine used on the Airbus A320neo, Boeing 737 MAX and Comac C919 aircraft.

With the role of Airbus as a European technology driver very clear, the A300B became the first commercial aircraft to use composites, in the leading and trailing edges of the vertical stabiliser and the radome.

Hawker Siddeley’s wing expertise, developed from that of its HS121 Trident rear-engined tri-jet, brought substantial benefits to Airbus. But a key question was how to transport these massive components from the factory near Chester on the England/North Wales border, to Toulouse in landlocked southwestern France for final assembly.

Enter the Aero Spacelines Super Guppy, the outsized, quad-prop converted from a Boeing C-97 Stratofreighter, the military equivalent of the Boeing 377 Stratocruiser. The Guppy shipped A300 wings and other components from across Europe that would not fit inside the relatively constrained loading gauges of European roads and railways.

Fittingly, the A300 itself succeeded the Super Guppy: the A300-600ST Super Transporter used the same conversion idea in the mid-1990s, growing in size, speed and efficiency. The large white aircraft’s nickname, Beluga, was eventually adopted as its official moniker by Airbus. These aircraft are still in operation, although they will eventually be succeeded by the A330-based Beluga XL, aircraft themselves transported to assembly by the A300 version of the Beluga.

If the A300A vs A300B question became complicated, the demands on how long the A300B should be became even more so. The original aircraft, the A300B1, was not large enough for Air France’s needs, so Airbus stretched it by five frames to become the A300B2.

An extended range version, the A300B4, was produced in the 1970s for Korean Air, and eventually nine variants from A300B1-9 were conceived, though not all were ordered or built.

Swissair and Lufthansa drove development of a shorter A310 — technically known as the A300B10 — which later fed back its redesigned rear fuselage and empennage to the A300-600 version of the B4 frame size.

The first two-pilot flightdeck was also created on the A310, since the A300 had retained both analogue dials and three flight crew. This two-pilot version was also adopted on the A300-600, though retaining the yoke-style controls of the A300B, since the now signature Airbus sidestick arrived only with the A320’s fly-by-wire systems.

Hundreds of A300s are still flying, and its legacy will fly for decades more

Altogether, Airbus would sell 816 A300 family aircraft, of which 561 were A300s and 255 A310s, and more than 300 are still in service. At the last count from Airbus earlier in 2019, 237 A300s and 70 A310s were still operating.

Many are freighters: FedEx has more than 80 in service, split between A300s and A310s, while UPS has over 50 A300s, most of which were very late models produced in the 2000s for the cargo market. Cargo carrier Air Hong Kong operates a further 10 A300s, while Canadian leisure airline Air Transat still uses its old A310s in passenger service, although these are being replaced by the A321LR version of the A321neo family.

Dozens of A300 family aircraft still operate in the unique circumstances in Iran, with Iran Air and Mahan Air the largest operators. Twenty are VIP aircraft worldwide, while the rest are in handfuls here and there around the world in secondary and tertiary markets.

But the A300’s legacy goes beyond those 816 aircraft. After the original A300B1-B8 aircraft concepts, the A300B9 and B11 evolved into the A330 and A340, which shared the same fuselage width, and indeed still share the same cabin layout: 2-4-2 in economy class for the majority of passengers, although an ultra-narrow 3-3-3 layout was and still is used by some leisure, charter and low-cost operators.

In the then first-class, the standard was a popular 2-2-2 configuration, still seen in many A330 and A340 business class seats today on airlines that are not competitive on the basis of passenger experience, such as Lufthansa, or in fleets serving less experience-sensitive markets, such as Qatar Airways.

The A330neo is still a part of Airbus’ strategy, although the irony for Airbus is that it seems to need an aircraft around the size of the A300 and A310 once more to serve the middle of the market between the A321 and the A330. Something like the 54m-long A300 or 47m-long A310 could fit well between the 45m-long narrowbody A321neo and the 58m-long widebody A330-800neo, which of course shares the A300’s fuselage size.

Christian Scherer, Airbus’s chief commercial officer, calls the A321neo the “rock” and the A330neo the “hard place” between which the European airframer is pinning the middle of the market. But the heavier, long-haul-optimised A330neo has yet to prove itself in the middle-of-the-market fight.

Is there room for one more size option of the A300’s venerable airframe in Airbus’s future?

VIDEO: A look at the first flights of the A310, A320, A340, A330, A380 and A400M from the Airbus YouTube channel.

This story first appeared in the July 2019 edition of Australian Aviation. To read more stories like this, subscribe here.