The idea of flying in the cargo deck might conjure the colloquial image of cattle class but if French aeronautical engineer Florian Barjot has his way, putting passengers in the bowel of the plane could be the next big travel thing.

Barjot’s EarthBay concept unveiled at the recently concluded Aircraft Interiors Expo Americas in Los Angeles would offer airlines a solution to the struggling and over-catered cargo market but also a trip for passengers with a view through floor-to-ceiling glass windows embedded in an aluminium and titanium frame for unimpeded views of the sky and earth.

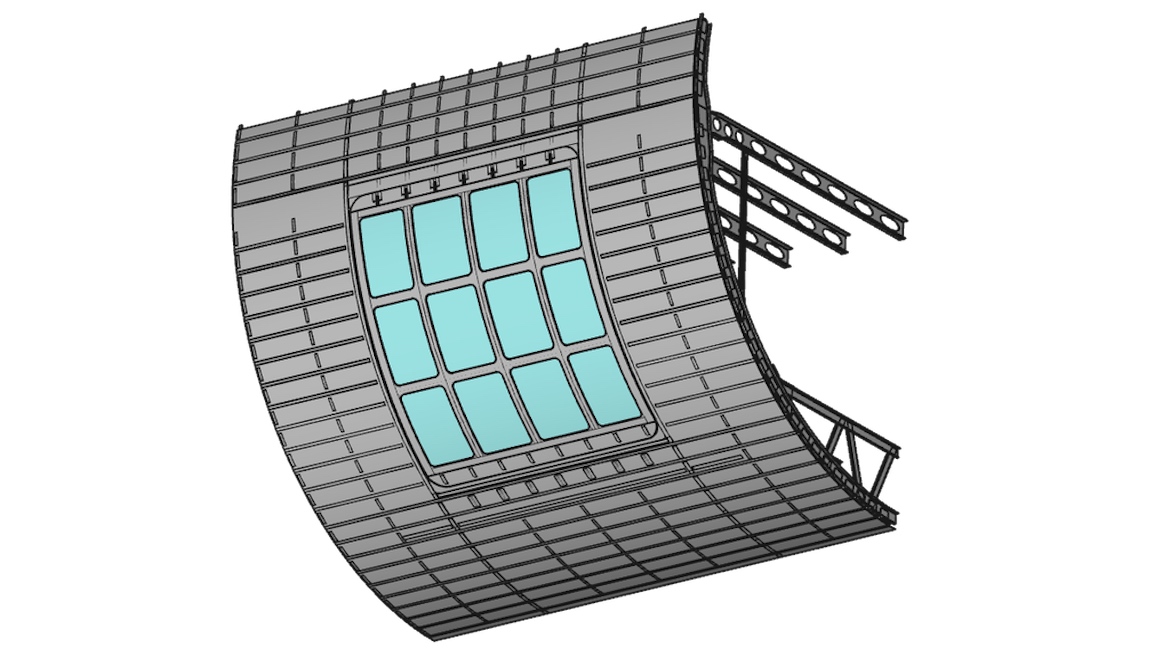

The multi-windowed frame would replace the aircraft cargo door, bringing light into the lower deck with access through an internal staircase.

Giving the passenger wide views through glass would give airlines the power to market an “exclusive experience”, Barjot said in a statement, with wide-body aircraft the core market for the concpet due to the cargo bay dimensions.

“Both Airbus and Boeing forecast an increase in this market segment from 4,100 aircraft today to 9,100 in 2036,” Barjot said.

“Making profits is challenging for the air freight sector. Many long-haul flights are operated with cargo bays more than half empty, while airfreight activity requires significant logistics costs and reliable and expensive software.

“In addition, freight transportation is not part of the business model of many low-cost or charter airlines.

“Refurbishing the forward cargo bay as a passenger cabin will have limited impact on the freight activity as the aft cargo bay would be enough to carry in many cases.”

Barjot said the possibility of transferring galleys or toilets to the hold would free up valuable space on the main deck, the addition of stairs notwithstanding.

To illustrate the concept, Barjot detailed in case studies different configurations, which he said could generate up to $US4 million a year through the extra space increasing capacity.

In one example, Barjot said on an aircraft with 12 business class seats, 338 economy seats and a freight load factor of 40 per cent, moving the 12 business seats to the lower deck with the necessary supplies such as water, waste and air conditioning would enable a further 18 economy class seats to be added to the upper deck.

The same quantity of freight (40 per cent) would be carried in the aft cargo compartment.

Barjot has estimated retrofitting a plane during a heavy maintenance check with this business class configuration on the lower deck, including the new windowed cargo door replacement, moving main deck galleys, new blocks of economy seats on the main deck, the staircase, a new crew area and toilets would cost about $US2.55 million per aircraft.

Assuming an 80 per cent occupancy rate on 700 flights per year with an average income per seat per flight of US$400 he arrived at the additional $US4 million a year per aircraft in revenue. However, if the freight load factor was more than 40 per cent, it would be necessary to compare the loss of cargo with the gain from passenger revenue.

In another case study, Barjot estimated the cost of reconfiguring economy, premium economy and business class on the main and lower deck at $2.615 million, with the possibility of an increase in revenue of $US3.5 million per year.

Barjot conceded, however, that his idea had operational limits. He said for security reasons passengers would need to be seated on the main deck during taxiing, take-off and landing before taking their seats in the hold once the flight reached cruise.

Given that the concept was based on an average of 80 per cent occupancy, there would be enough room for passengers to temporarily take the 20 per cent of vacant seats before reaching cruise altitude. He did not explain how his concept would work though with a full aircraft.

His goal is for the hold space to be utilised by passengers in aircraft by 2024. Before then, prototypes would need to be built, load testing and stress analysis conducted, as well as collaboration with the US Federal Aviation Administration and European Union Aviation Safety Agency for certification.