In this cross-posting with The Conversation, health researchers Liz Breen and Sarah Schiffling discuss the logistics required in transporting vaccines, and the aviation industry’s role in that.

In this cross-posting with The Conversation, health researchers Liz Breen and Sarah Schiffling discuss the logistics required in transporting vaccines, and the aviation industry’s role in that.

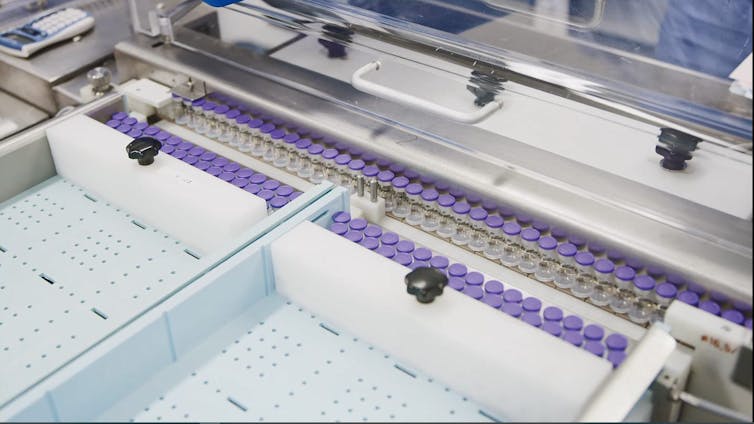

The Pfizer/BioNTech vaccine has just been approved for widespread use in the UK and the government has ordered 40 million doses – enough to vaccinate 20 million people. The first 800,000 doses are expected to be delivered to the UK in the next few days.

The Moderna and Oxford/AstraZeneca vaccines also appear to be close to gaining approval by regulatory authorities. The vaccines promise billions of people around the world a return to normality as the pandemic is brought to an end.

After the great effort put into developing and testing these vaccines, another huge task lies ahead: the logistics of vaccine distribution.

A supply chain like no other

This is the biggest vaccine supply chain challenge ever, but the challenges are not new. The distribution of the Ebola vaccine relied on establishing ultra-cold chains in remote parts of the world. By bundling the knowledge and experience of the public and private sectors and humanitarian organisations, the vital supply chain for COVID vaccines can be successful.

A few key issues need to be considered in vaccine logistics: the international transport requirements, storage needs, local distribution needs, and production locations. And these issues can differ from one vaccine to another.

Moderna’s COVID vaccine needs to be transported and stored at minus 20 degrees and has a shelf-life of six months. At the final destination, such as a clinic or pharmacy, it can be stored in a regular fridge but must be used within 30 days. The Pfizer/BioNTech vaccine must be kept at minus 70 degrees and can be kept in a regular fridge for just five days.

If the right infrastructure isn’t in place, a lot of waste could ensue. According to the World Health Organisation, up to 50 per cent of vaccines are wasted globally due to inadequate logistics infrastructure. Applied to COVID-19, this could translate to the loss of billions of vaccine doses – an expensive error in logistics planning and execution.

Vaccine hesitancy can also lead to waste. Many of the COVID vaccines being developed require two shots. If people who are hesitant about the vaccine change their mind after the first shot and don’t return for the second, it will render the vaccine ineffective – and many doses will be wasted.

The international transport capacity needed to distribute a COVID vaccine has been estimated to be between 8,000 (IATA) and 15,000 (DHL) flights. Details will depend on the precise requirements for storage, packaging and transport. For example, the use of dry ice to achieve consistent temperatures of minus 80 degrees limits the capacity on board an aeroplane.

The decrease in passenger flights as a result of the pandemic may also be an issue; most air freight is moved in the cargo hold of passenger planes.

Frankfurt Airport in Germany, which was handling 120,000 tonnes of pharmaceutical products in 2019, has significantly increased its capacity in 2020. Its task force is anticipating the rise in demand for temperature-controlled storage and handling.

Storage requirements are likely to influence the local distribution networks as well. Some countries are already setting up big vaccination centres to ensure that the necessary infrastructure is in place and the vaccine is not going to spoil because of poor storage conditions at GP surgeries.

In the UK, it has been suggested that a range of healthcare professionals, such as dentists and healthcare scientists, will administer the COVID vaccines, so the local logistics and storage across a wide range of sites will have to be coordinated.

And globally, central vaccination locations are not an option for many less densely populated areas, as well as mountainous regions or those with many islands. There are also concerns that many would not be able to travel to be vaccinated – for example, older people or those in war-torn areas.

Learning from the automotive industry

Some vaccines, such as the mRNA vaccines that Pfizer and Moderna have developed, are what are known as “labile”. That is, they degrade each time they are moved and can eventually become inactive. A solution to this problem is relocating production facilities nearer to those who need to be immunised.

This has been done successfully by the automotive industry and many others which have shifted their factories to countries with large consumer markets. Coupled with the risk of rendering vaccines ineffective due to lack of correct temperature-controlled storage and logistics, this makes the distribution of some of these COVID vaccines a risky business.

Reaching the vulnerable

This pandemic is a global crisis, and the calls for global responses are strong. Indeed, several of the promising vaccines have been developed through international collaborations. Much co-operation will be needed to ensure that the most vulnerable are vaccinated – and not only in rich nations. But among all the inspiring stories of co-operation, it is important to remember that national and commercial interests are strong and will continue to shape the international response, especially in terms of logistics.

These are not entirely unprecedented times. While the scale of the required vaccine supply chain is immense, the challenges are not new. By drawing on expertise from diverse sectors and cooperating globally, COVID-19 vaccines can reach all those who need them.